Acoustic properties of selected high strength

thermosetting plastic composites at ultrasonic frequencies

David Wuchinich

Director

Modal Mechanics

2012 Ultrasonics

Industry Association Symposium

San Francisco, CA

© 2011 David Wuchinich

Abstract

High strength thermosetting plastic composites

provide static strengths comparable to some metals while having densities

slightly greater than water and an acoustic impedance

comparable to aluminum. To evaluate their use as ultrasonic resonators

measurements were made of their density, extensional sound velocity and elastic

constant. To determine their utility and limitations as ultrasonic horns

operating at substantial displacements and stress their Q was also measured at

stress levels in the range of 50 MPa (7300 psi) at 20 kHz. It was found that

one of these materials, although more costly than metals, may serve well as a

replacement for metal horns for output displacements in the range of 75 microns

(3 mils), peak-peak at 20 kHz, particularly in applications where low weight

and long length is desired.

Introduction

The cyclic fatigue strength of many

thermoplastics is available from a number of sources.[1] However these data were obtained almost

exclusively using bending or torsional strain at

frequencies in the range of 1-10 Hz. Niermac

reported measurements of the Q of polymers at imposed cyclic pressures below 1

atm at a frequency of 1500 Hz.[2] The properties of

thermo and thermosetting plastics at substantial strain at ultrasonic frequencies

have been sparsely evaluated. Menges

and Barbari studied cyclic loss in polycarbonate and polypropylene at 20 kHz at

strains in the range of 0.002.[3] Earlier, Mason evaluated, at a frequency of

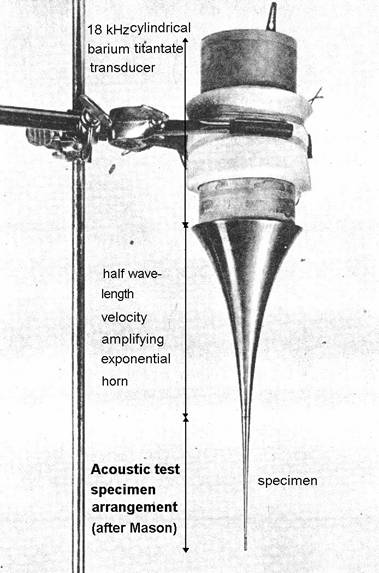

about 18 kHz, the Q and fracture strain of Bakelite[4]. His apparatus is shown in Figure 1. His acoustic arrangement is followed in this

report.

Figure 1 – Mason’s test apparatus for

measurement of acoustic loss

Because of ease with which modern thermosetting

composite plastics, which offer static strengths substantially larger than

thermoplastics, can be formed and cured into complex shapes they are an

attractive candidate for mass production as ultrasonic horns. A comparative evaluation

of their dynamic modulus and acoustic loss at ultrasonic frequency at strains

of practical interest where their use, for example, in producing cavitation

initiated sono-chemical reactions for consumer and industrial products, may assist

their consideration for use in such applications. This report relates an evaluation, in the regime

of practical interest, of three such composites: G9, consisting of a woven fiberglass fabric

impregnated with a melamine resin; G11, fiberglass cloth impregnated with an

epoxy resin; unidirectional carbon fiber impregnated with a bisphenol epoxy

resin[5]. For purposes of reference, an evaluation was

also made of unfilled polycarbonate for comparison with Menges’ report made

under similar frequency and strain conditions.

Test

Method

Computation of the elastic modulus of the

materials was made by measurement of the frequency of their first free-free

flexural vibration[6]. Although this method can be readily employed

for metal samples in lengths of as little as 15 cm (6 in.), composites, having

a much lower Q, require much longer sample lengths, on the order of 100 cm, so

that the duration of vibration is sufficiently long to permit measurement.

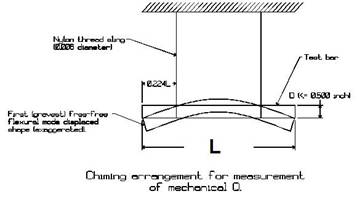

By suspending the sample at each of two nodes

of vibration, located 22.4 percent of the sample’s length from each end, and

striking its center the frequency is read from an oscilloscope or frequency

meter connected to a microphone held in proximity. Figure 2 illustrates test arrangement.

Figure 2 – Measurement of elastic

modulus by chiming

If f is the measured frequency of vibration, l

and D the sample’s length and diameter, the extensional sound velocity, c, can

be computed as[7]:

(1)

(1)

From weight and dimensional measurements the

density, ρ, can be

found and thus the elastic modulus, Y, computed as

![]() (2)

(2)

Table 1 summarizes the measurement

results. For purposes of comparison,

the values for 6Al-4V titanium have been included.

Table 1 – Density and Modulus of

test samples

|

Material |

Density,ρ, kg/m3 (lbsf/in3) |

Modulus, Y, GPa (Mpsi) |

Sound velocity,c, m/s (103 in/s) |

|

polycarbonate |

1190 (.043 |

2.5 (0.364) |

1450 (57.2) |

|

G9 |

1850 (.067) |

29 (4.16) |

3700 (145) |

|

G11 |

1990 (.072) |

29 (4.19) |

3800 (149) |

|

Carbon Fiber |

1605 (0.058) |

112 (16.3) |

8400 (331) |

|

6Al-4V Titanium |

4420 (0.160) |

110 (16) |

5080 (200) |

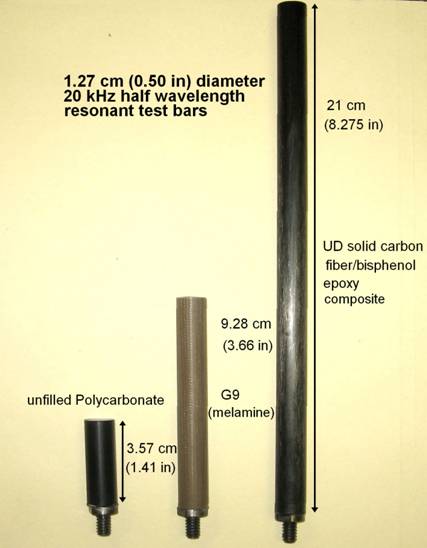

Samples were then cut from stock rod having a

length, ls = c/2f, computed to be equal to

a half wavelength of extensional resonance at 20 kHz. Figure 3 is a photograph of three of the samples.

Note the disparity in lengths between the

samples.

Figure 3 – 20 kHz extensionally

resonant plastic test rods

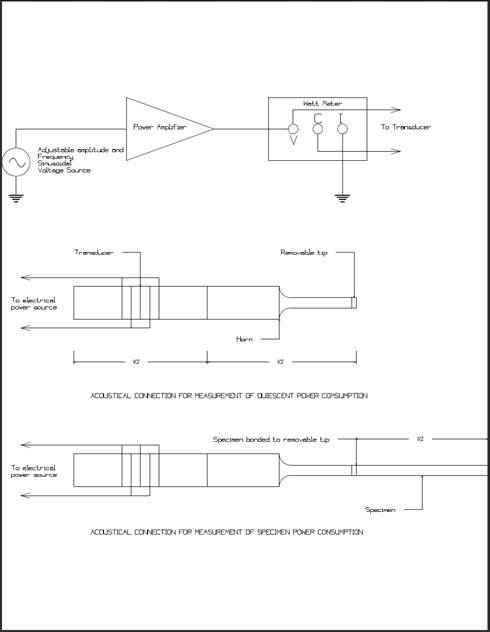

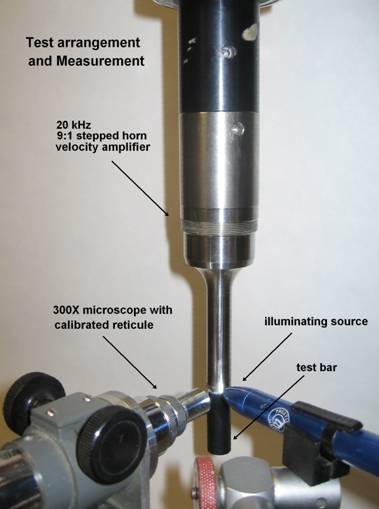

A 20 kHz piezo-electric transducer equipped

with a 9:1 velocity transforming stepped horn was provided for the tests. This transducer was driven by a power

amplifier whose input was provided by a variable frequency and amplitude

sinusoidal signal generator. A high

frequency watt meter (Clarke-Hess Model 255)[8] was

connected between the power amplifier’s output and the transducer. The schematic test setup is shown in Figure

4.

Note that the watt meter is connected to register only

the power consumed by the transducer and not that as well consumed by the

meter’s current sensing shunt. As such,

it’s reading of real average power delivery to the transducer appears negative.

Figure 4 - Electrical and Mechanical test

configuration

Prior to attaching a specimen, the power

consumption of the transducer-horn combination was measured at various

vibration amplitudes, as determined by a 300X microscope equipped with a

calibrated reticule, at the free end of the horn, which contained a removable

tip. The vibration was measured at the

maximum stroke point in microns (mils) peak-peak. The equipment arrangement is shown in Figure

5 with a specimen in place.

Figure 5 - Vibration measurement and location

The horn with the tip attached was resonant at 20.0

kHz. Following measurement of the power

consumed by transducer and horn, the tip was removed from the horn and bonded

to a sample using Emerson and Cummings Eccobond G909 structural epoxy. This

high strength epoxy cures at 100 oC, a temperature unlikely to

affect the structure of the specimens. The

power consumption at maximum stroke and the resonant frequency was measured for

successive increases in vibration amplitude.

Q is defined as 2π(Energy,

Es, stored in vibration per cycle)/(Energy lost, El, per

cycle of vibration). From the power

measurements, the vibration amplitude, the mass of the sample and the frequency

of vibration, Q can be computed as:

(3)

(3)

Where m is the mass of the specimen, v is velocity of

vibration of the free faces = 2πfs/2, where s is the peak to peak

excursion, Pt is the power consumption measured with the specimen

attached and Pq the power at

the same excursion measured for the transducer-horn alone and f is the

resonant frequency. With the

substitution, v = 2πf(s/2), s being the peak-peak excursion, made:

(4)

(4)

This computation assumes that the resonant frequency measured

for the transducer-horn system remains the same when the specimen is attached,

a condition that prevailed within 0.1 percent during testing.

Results

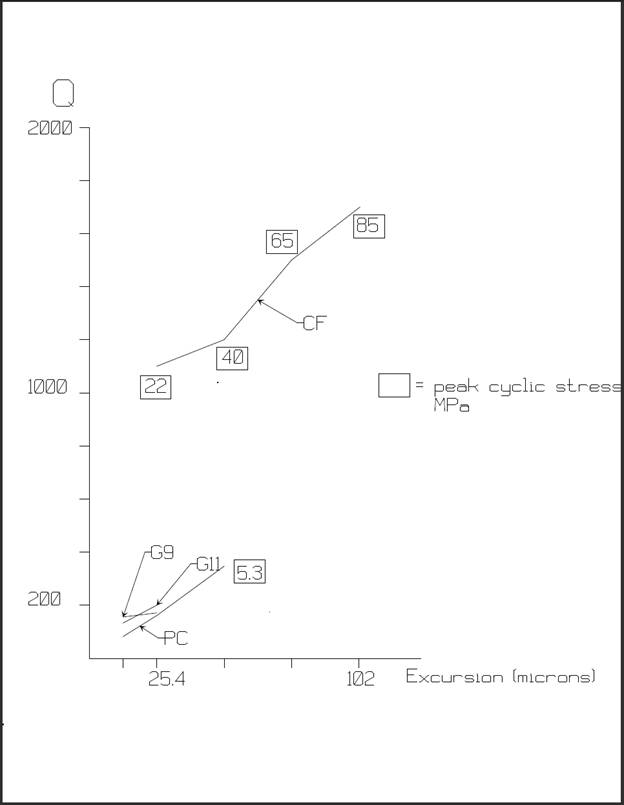

The Q obtained at successively increased excursion in

each of the samples is shown in Figure 6.

Figure 6 - Acoustic Q vs. resonant

free end excursion

Discussion

The value of Q obtained for polycarbonate is in

approximate agreement with that of 100 obtained by Menges3. Both epoxy composites, G9 and G11, exhibit

similar values which compare rather starkly with those obtained for Titanium of

20,000[9]. Clearly the uni-directional carbon fiber

sample exhibits much lower acoustic loss than either of the fiberglass-epoxy

composites or polycarbonate. The author

has found, however, that polycarbonate is capable of continuously surviving

operation at 20 kHz cyclic stresses of approximately 1.4 MPa (200 psi) if

provision is made, given the low thermal conductivity of plastics compared to

metals, for cooling the material. This

level of stress amounts to an excursion of 15 microns (0.6 mil) in a right

prismatic extensional half wave length resonator.

Because both G9 and G11 exhibit an increased sound

velocity compared to polycarbonate, their half wavelength substantially exceeds

that of polycarbonate. As a result, the

power required to maintain vibration above 50 microns was beyond the electrical

drive capability of the testing equipment.

It appears that these materials

may be capable of sustaining vibration levels larger than those measured here

but, even at the 15 micron level, given their greater volume their power

consumption is about 2.5 times that consumed by polycarbonate in half wave

extensional resonance.

It seems likely that carbon fiber is capable of

continuous operation at larger cyclic stresses, in the range of 70 MPa,

corresponding to an excursion of 75 microns (3 mils), especially given its

thermal conductivity, even in the direction perpendicular to fiber length, in

the range of 0.9 W/mK compared with the value for polycarbonate of 0.2 W/mK[10]. Thermal conductivity in the direction

parallel to the fiber length is at least 40 W/mK, comparable to martensitic

stainless steels. In addition, CF is

electrically conductive.

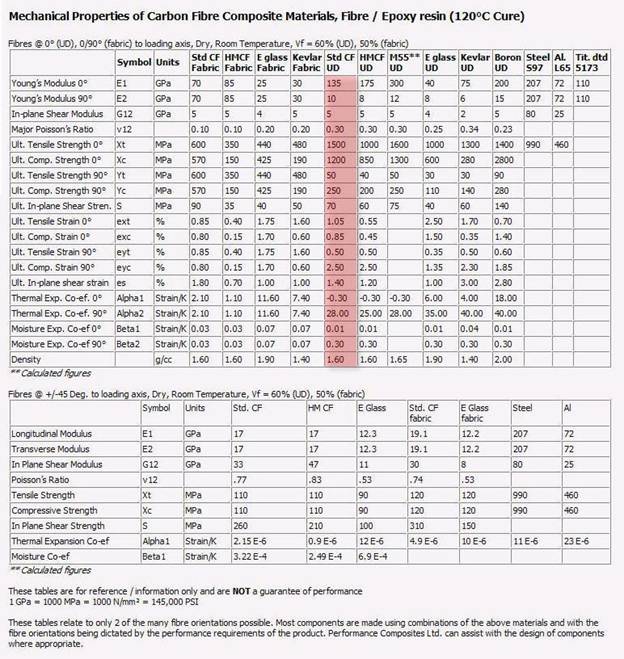

The mechanical properties of carbon fiber composites are

shown in Figure 7. Of note here is the anisotropy

of the UD material. The modulus in the

direction perpendicular to the fiber orientation is a tenth that in the aligned

direction. Horn should there be designed

so that direction of principal strain is coincident with the fiber lay. For example, in constructing blade horns, CF

slab blanks are normally made by laminating thin sections of composites each

having the carbon fibers uniformly aligned in one direction. This direction should correspond to the

direction of principal strain.

When considered for use as half wavelength resonators the

disparity in wavelength between CF and the metals, such as titanium or

aluminum, of which connected transducers and horns are commonly made, must be

taken into account. Threaded connections

are thus subject to differential movement between a metal stud and the carbon

or other plastic resonator. It has been

found experimentally that connections are durable when the stud itself is made

of the same plastic material used for the resonator or is made of a material

having the same wavelength as that plastic.

Figure 7 - Mechanical Properties of

Carbon Fiber Composites